Why use Textile Hose Sleeve for hydraulic hose?

|

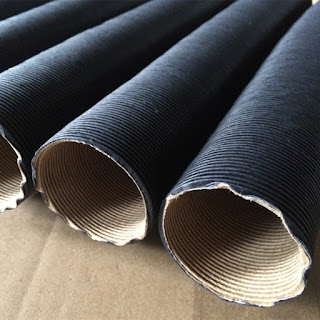

| Textile Hose Sleeve for hydraulic hose |

Textile hose sleeves, including those made from nylon, polyester, and polypropylene, offer several benefits for hydraulic hoses. Here's why you might use them:

1. Protection from Abrasion:

- Nylon Hose Sleeve: Nylon is known for its durability and resistance to abrasion. It provides excellent protection against physical wear and tear, extending the life of the hydraulic hose.

- Polyester Hose Sleeve: Polyester also offers good abrasion resistance, although it's generally not as tough as nylon. It's suitable for less demanding applications.

- Polypropylene Hose Sleeve: Polypropylene is another option that provides abrasion resistance, though it's often less common than nylon or polyester.

2. Improved Safety:

- Textile sleeves help prevent the hose from being damaged by external factors such as sharp edges or debris, which can cause leaks or bursts.

- They also provide some degree of fire resistance, depending on the material, enhancing overall safety.

3. Enhanced Aesthetics:

- Hose sleeves can improve the appearance of hydraulic systems by covering up the hoses, making them look more organized and less cluttered.

4. Temperature and Chemical Resistance:

- Nylon Hose Sleeve: Nylon can handle a wide range of temperatures and has some resistance to chemicals, although it may degrade with prolonged exposure to strong acids or bases.

- Polyester Hose Sleeve: Polyester also offers good temperature resistance and is more resistant to UV radiation, making it a good choice for outdoor applications.

- Polypropylene Hose Sleeve: Polypropylene has good resistance to chemicals and is suitable for a variety of environments.

5. Easy Installation and Maintenance:

- Nylon Hose Sleeve with Velcro: The addition of Velcro makes installation and removal easier, allowing for quick adjustments or replacements without having to disassemble the hydraulic system.

- Polyester Hose Sleeve with Velcro: Similarly, polyester sleeves with Velcro offer convenience and ease of use, which can be beneficial in maintenance scenarios.

6. Flexibility and Customization:

- Nylon and Polyester Hose Sleeves: Both materials are flexible and can be easily cut to length, allowing for custom fits on different hose sizes and shapes.

- With Velcro: Sleeves with Velcro are especially versatile, as they can be opened up and wrapped around hoses of varying sizes and configurations.

7. Cost-Effectiveness:

- Textile hose sleeves are generally affordable and can be a cost-effective solution for protecting hydraulic hoses compared to other more rigid or specialized protective measures.

In summary, textile hose sleeves are used to protect hydraulic hoses from physical damage, environmental factors, and chemical exposure while also providing benefits in terms of safety, aesthetics, and ease of maintenance. The choice of material and whether or not to use Velcro depends on the specific needs of your application, including the type of environment and the level of protection required.

Comments

Post a Comment