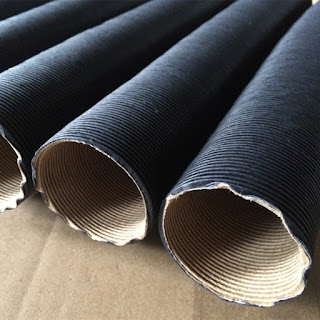

Why use the fiberglass braided sleeve?

Fiberglass braided sleeves are used for a variety of reasons, primarily related to their protective and insulating properties. Here are some of the main benefits:

Heat Resistance: Fiberglass is excellent at withstanding high temperatures. The sleeve can protect wires, cables, and hoses from extreme heat and thermal damage, which is particularly useful in automotive, aerospace, and industrial applications.

Insulation: The sleeve provides electrical insulation, helping to prevent electrical shorts and protect sensitive components from electrical interference.

Abrasion Resistance: The braided construction of the fiberglass sleeve offers a degree of mechanical protection, shielding the underlying wires or cables from abrasion, cuts, and other physical damage.

Chemical Resistance: Fiberglass is resistant to many chemicals and solvents, making the sleeve a good choice for environments where exposure to harsh substances is a concern.

Flexibility: Despite its protective qualities, fiberglass braided sleeves are flexible and can be easily applied to cables and hoses of various sizes and shapes.

Durability: The sleeve can withstand long-term wear and tear, extending the lifespan of the components it protects.

Overall, fiberglass braided sleeves are a versatile and effective solution for protecting cables, wires, and hoses in demanding environments.

|

| fiberglass braided sleeve |

Comments

Post a Comment