Why use aramid braided sleeve?

Aramid braided sleeves are used primarily for their exceptional protective qualities. Here are some key reasons why they might be chosen:

High Strength: Aramid fibers, such as Kevlar, are known for their high tensile strength. The braided sleeve provides excellent protection against abrasion, cuts, and impacts.

Heat Resistance: Aramid materials are heat-resistant and can withstand high temperatures without degrading. This makes them suitable for applications where thermal protection is required.

Chemical Resistance: Aramid fibers generally have good resistance to various chemicals, making the sleeves useful in environments where chemical exposure is a concern.

Lightweight: Despite their strength, aramid fibers are relatively lightweight, which helps in applications where weight is a consideration.

Flexibility and Durability: The braided construction offers flexibility and durability, allowing the sleeve to conform to different shapes and provide long-lasting protection.

Electrical Insulation: Aramid sleeves can offer some level of electrical insulation, protecting against electrical shorts or damage in certain applications.

Overall, aramid braided sleeves are used in industries like automotive, aerospace, and electronics for their protective qualities and ability to withstand harsh conditions.

|

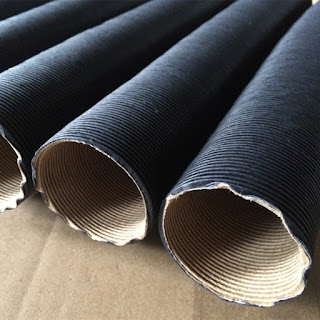

| aramid braided sleeve |

Comments

Post a Comment