What is the purpose of a Nylon Hose Sleeve Protection?

Understanding Nylon Hose Sleeve Protection: Applications, Benefits, and Performance

In various industrial and commercial environments, protecting hoses from damage and wear is crucial. Nylon Hose Sleeve Protection is a versatile solution designed to extend the lifespan of hoses and maintain operational efficiency. Here’s an in-depth look at what Nylon Hose Sleeve Protection is, its performance features, and the diverse scenarios in which it proves invaluable.

What is Nylon Hose Sleeve Protection?

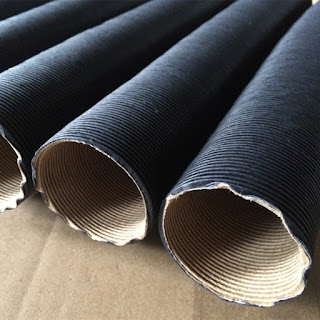

Nylon Hose Sleeve Protection is a durable, flexible cover made from high-strength nylon. It is engineered to shield hoses from abrasion, impacts, heat, and other environmental hazards. By wrapping hoses with this sleeve, you protect both the hose itself and the equipment it services, reducing the need for frequent replacements and repairs.

Key Performance Features

Abrasion Resistance: The nylon material provides a robust barrier against physical wear and tear. This is particularly valuable in high-friction applications where hoses are subject to constant movement or contact with rough surfaces.

Heat Resistance: Nylon sleeves can withstand elevated temperatures, making them suitable for environments where hoses are exposed to heat or hot fluids. This ensures that the hose remains intact and functional even under high-temperature conditions.

Chemical Resistance: While nylon is not impervious to all chemicals, it offers good resistance to many common industrial substances, protecting the hose from corrosive effects.

Flexibility and Ease of Installation: The sleeve’s flexibility allows it to conform to various hose sizes and shapes. It is easy to install, often requiring just a simple slide-on application.

Enhanced Safety: By protecting hoses from external damage, nylon sleeves reduce the risk of hose failures, which can lead to hazardous leaks or system malfunctions.

Practical Applications

1. Automotive Industry: In automotive repair and manufacturing, hoses are frequently exposed to harsh conditions. Nylon hose sleeves protect brake lines, fuel lines, and hydraulic hoses from road debris, heat from the engine, and mechanical wear, ensuring reliable performance and safety.

2. Aerospace Sector: Aerospace applications require hoses to endure extreme temperatures and pressures. Nylon sleeves safeguard fuel, hydraulic, and pneumatic hoses from abrasion and high-temperature effects, crucial for maintaining aircraft safety and operational efficiency.

3. Construction and Heavy Machinery: Heavy machinery and construction equipment operate in rugged environments. Nylon hose sleeves shield hydraulic lines and other critical hoses from abrasive materials, impacts, and extreme temperatures, reducing downtime and maintenance costs.

4. Industrial Manufacturing: In manufacturing plants, hoses often handle high-pressure fluids and are subjected to constant movement. Nylon sleeves protect these hoses from wear and tear, ensuring uninterrupted production and minimizing the risk of fluid leaks.

5. Marine Applications: In marine environments, hoses face exposure to saltwater, UV radiation, and physical abrasion. Nylon hose sleeves provide an additional layer of protection against these harsh conditions, prolonging the lifespan of hoses used in boats and offshore equipment.

User Experiences

Automotive Mechanic, John D.: “Using nylon hose sleeves in my shop has significantly reduced the number of hose replacements we needed. The sleeves stand up to the tough conditions of daily use and help keep our vehicles running smoothly.”

Aerospace Engineer, Sarah L.: “In aerospace applications, hose protection is non-negotiable. Nylon sleeves have proven to be an effective solution for safeguarding our hydraulic and fuel lines, ensuring we meet stringent safety standards.”

Construction Manager, Mike R.: “The wear and tear on construction machinery hoses is immense. Nylon sleeves have been a game-changer, extending the life of our hoses and reducing maintenance downtime on site.”

Marine Technician, Emily W.: “Marine environments are tough on equipment, but nylon hose sleeves have held up remarkably well against saltwater and UV exposure. They’re a must-have for maintaining our hoses in peak condition.”

In summary, Nylon Hose Sleeve Protection offers a cost-effective and efficient solution for safeguarding hoses across various industries. By incorporating these protective sleeves, businesses can enhance the durability of their hoses, reduce maintenance costs, and ensure safer operations.

|

| Nylon Hose Sleeve Protection |

Comments

Post a Comment