What is the purpose of a Braided Fiberglass Sleeve Heat Treated?

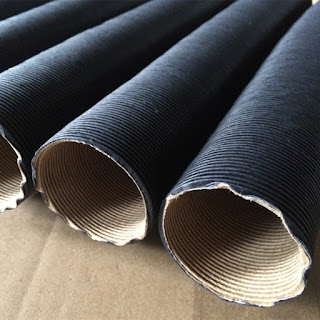

A Braided Fiberglass Sleeve Heat Treated is a protective material used to shield cables and hoses from high temperatures and physical damage. Made from woven fiberglass and treated to enhance its thermal resistance, it can withstand temperatures up to 1,000°F (538°C). The sleeve provides excellent insulation, preventing heat transfer and reducing the risk of fire or thermal damage to sensitive components.

In automotive applications, it protects fuel lines and electrical wires from engine heat. In aerospace, it shields hydraulic hoses from extreme temperatures during flight. In industrial settings, it covers equipment cables to safeguard against hot surfaces and abrasion.

For instance, an automotive technician might use this sleeve to protect wiring near the exhaust manifold, while a factory might deploy it to encase hoses in high-temperature machinery. Users appreciate its durability and effectiveness in preventing heat-related failures.

|

| Braided Fiberglass Sleeve Heat Treated |

Comments

Post a Comment