What is the application of silicone fire sleeve?

A silicone fire sleeve is a specialized protective sleeve made from high-quality silicone rubber materials, designed to withstand high temperatures and provide fire resistance. These sleeves find numerous applications across various industries where protection against extreme heat and fire is crucial. Some common applications of silicone fire sleeves include:

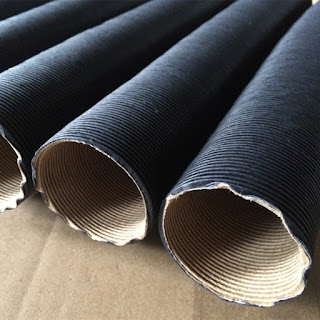

silicone fire sleeve

silicone fire sleeve

silicone fire sleeve

Automotive and Racing: Silicone fire sleeves are widely used in automotive and racing applications to protect fuel lines, hydraulic hoses, wiring harnesses, and other critical components from exposure to high temperatures and flames. They help prevent fuel line ruptures, fluid leaks, and electrical failures due to heat-related damage.

Aerospace and Aviation: Silicone fire sleeves are utilized in the aerospace and aviation industries to protect aircraft wiring, fuel lines, and hydraulic systems from fire hazards and heat-related failures. They are essential for ensuring the safety and reliability of aircraft components in extreme operating conditions.

Industrial Machinery: In industrial settings, silicone fire sleeves are used to protect hoses, cables, and pipes in machinery and equipment from exposure to heat, sparks, and molten metal splashes. They help prevent equipment damage, downtime, and workplace accidents in foundries, steel mills, and other manufacturing facilities.

Marine and Offshore Applications: Silicone fire sleeves are employed in marine and offshore environments to protect hydraulic hoses, cables, and electrical wiring from fire hazards, oil spills, and exposure to seawater. They are crucial for maintaining the integrity and safety of equipment on ships, offshore platforms, and marine vessels.

Electrical and Electronics: Silicone fire sleeves are used in electrical and electronic applications to provide fire protection and insulation for wires, cables, and connectors. They help prevent short circuits, electrical fires, and equipment damage caused by overheating or electrical faults in industrial, commercial, and residential settings.

Mining and Construction: Silicone fire sleeves are utilized in mining and construction equipment to protect hydraulic hoses, pneumatic lines, and electrical cables from heat, abrasion, and harsh environmental conditions. They help ensure the reliability and durability of equipment in demanding work environments.

Oil and Gas Industry: Silicone fire sleeves are used in the oil and gas industry to protect hoses, pipes, and instrumentation lines from exposure to high temperatures, flames, and chemical hazards. They are essential for ensuring the safety and integrity of equipment in refineries, petrochemical plants, and offshore drilling rigs.

Overall, silicone fire sleeves offer reliable and effective protection against extreme heat and fire hazards in various applications, making them indispensable for safety-critical industries and environments where fire protection is paramount.

Anti Vibration Rubber Pads - One of the leading EPDM Rubber Gaskets manufacturers and suppliers in Mumbai, India. EPDM rubber gaskets designed for excellent resistance to weather, ozone, and temperature extremes, making them ideal for outdoor and industrial sealing applications. EPDM Rubber Gaskets are manufactured from high-quality EPDM material, known for its superior resistance to weathering, ozone, and aging.

ReplyDelete