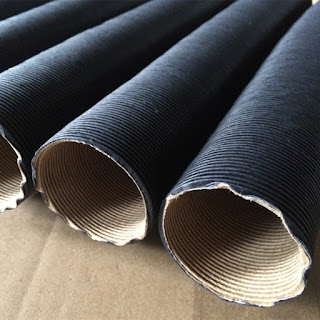

Heat Sleeve Braided Fiberglass 500-2200 Degree F

A heat sleeve braided from fiberglass is a protective covering designed to withstand high temperatures. It is typically used for insulating and shielding various components in applications where extreme heat is generated. Here are some key features and benefits of a heat sleeve braided with fiberglass:

Temperature resistance: Heat sleeves made from braided fiberglass are specifically engineered to withstand high temperatures. They can typically handle temperatures ranging from 500 to 2200 degrees Fahrenheit (260 to 1200 degrees Celsius). This makes them suitable for use in applications where intense heat is present, such as automotive exhaust systems, industrial machinery, or high-performance engines.

Heat insulation: The primary purpose of a heat sleeve is to provide thermal insulation. The braided fiberglass construction acts as a barrier, preventing heat from radiating outwards and protecting nearby components or materials from heat damage. This can help in reducing the risk of heat-related failures, ensuring better performance and longevity of the protected components.

Durability: Fiberglass is known for its strength and durability. Heat sleeves made from braided fiberglass are resistant to abrasion, chemicals, and mechanical wear. They can withstand harsh operating conditions and maintain their protective properties even in demanding environments.

Easy installation: Heat sleeves braided with fiberglass often feature a flexible and expandable design, making them relatively easy to install. They can be slipped over the component or wiring that needs protection, and some sleeves may have a hook-and-loop closure or high-temperature adhesive for secure fastening.

Fire resistance: Fiberglass is inherently fire-resistant, which adds an extra layer of safety when using a heat sleeve braided with this material. It helps to contain potential flames and prevent the spread of fire.

When selecting a heat sleeve braided with fiberglass, it is important to choose a size that fits your specific application. The sleeve should have a diameter that matches the component or wiring you intend to protect. It's also crucial to ensure proper installation and secure fastening to maximize the effectiveness of the sleeve.

Please note that while fiberglass sleeves provide excellent heat resistance, they may not be suitable for direct contact with hot surfaces or moving parts. Always refer to the manufacturer's specifications and guidelines to ensure proper usage and compatibility with your specific application.

Comments

Post a Comment