What materials are commonly used for exhaust lagging?

Several materials are commonly used for exhaust lagging due to their heat-resistant properties and effectiveness in insulating the exhaust system. The choice of material depends on factors such as temperature requirements, durability, and application. Here are some commonly used materials for exhaust lagging:

Ceramic Fiber: Ceramic fiber is a popular choice for exhaust lagging due to its excellent thermal insulation properties and high-temperature resistance. It can withstand extreme temperatures, making it suitable for high-performance applications. Ceramic fiber is lightweight, flexible, and offers good heat retention capabilities.

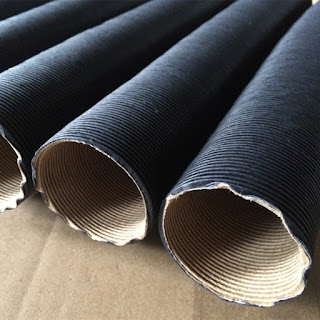

Fiberglass: Fiberglass is another commonly used material for exhaust lagging. It consists of fine glass fibers woven together or formed into a mat. Fiberglass is known for its durability, resistance to high temperatures, and affordability. It provides effective thermal insulation and is relatively easy to install.

Basalt Fiber: Basalt fiber is derived from volcanic rock and offers excellent thermal insulation properties. It is highly resistant to high temperatures and can withstand thermal shock. Basalt fiber is also known for its resistance to moisture and chemicals, making it suitable for harsh environments.

Silica Fiber: Silica fiber, also known as silica cloth or silica tape, is made from amorphous silica. It is known for its excellent heat resistance and low thermal conductivity. Silica fiber can handle extremely high temperatures and is often used in applications where thermal insulation and protection against radiant heat are critical.

Aramid Fiber: Aramid fibers, such as Nomex or Kevlar, are known for their exceptional strength, heat resistance, and flame retardancy. They offer good thermal insulation properties and are often used in high-performance and racing applications.

Aluminum Coated Materials: Some exhaust lagging materials feature an aluminum coating or foil layer. This aluminum coating provides additional reflectivity, helping to reflect radiant heat back into the exhaust system, further reducing heat loss.

Silicone-Based Materials: Silicone-based materials are known for their flexibility, high-temperature resistance, and durability. They are often used in exhaust lagging wraps, sleeves, or tapes. Silicone-based materials provide good insulation and are resistant to oil, chemicals, and moisture.

It's important to select materials specifically designed for exhaust lagging applications, as they are engineered to withstand the high temperatures and harsh conditions of the exhaust system. Consider factors such as the maximum temperature rating, installation requirements, and compatibility with the specific exhaust components when choosing the appropriate material for your exhaust lagging needs.

|

| What materials are commonly used for exhaust lagging? |

|

| What materials are commonly used for exhaust lagging? |

Comments

Post a Comment