What are the advantages of using Kevlar Braided Expandable Sleeving?

Using Kevlar Braided Expandable Sleeving offers several advantages, including:

High Strength: Kevlar fibers are known for their exceptional strength-to-weight ratio. Kevlar Braided Expandable Sleeving provides robust protection against abrasion, cuts, and mechanical stress, ensuring the longevity of cables, wires, and hoses.

Heat Resistance: Kevlar is highly resistant to heat and can withstand high temperatures without degrading or melting. Kevlar Braided Expandable Sleeving offers reliable thermal protection for cables and wires in applications where heat is a concern.

Chemical Resistance: Kevlar fibers exhibit excellent resistance to a wide range of chemicals, including acids, solvents, and oils. This makes Kevlar Braided Expandable Sleeving suitable for applications in industries where exposure to corrosive substances is common.

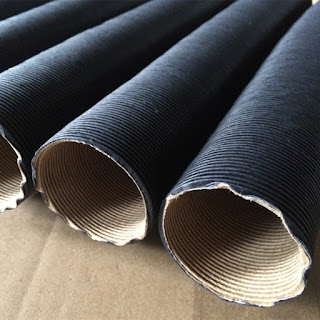

Flexibility and Expandability: The braided construction of Kevlar Sleeving allows for flexibility and expandability. It can easily accommodate different sizes and shapes of cables, wires, and hoses, making installation and maintenance more convenient.

Lightweight: Kevlar is a lightweight material, which means that the sleeving adds minimal additional weight to the protected components. This is particularly important in industries where weight reduction is a consideration, such as aerospace and automotive applications.

Electrical Insulation: Kevlar Braided Expandable Sleeving can provide electrical insulation for cables and wires. It helps prevent electrical interference, short circuits, and electrical hazards, ensuring the safe and reliable operation of electrical systems.

Cut and Abrasion Resistance: The strong and durable nature of Kevlar fibers offers excellent resistance to cuts and abrasion. Kevlar Braided Expandable Sleeving protects cables, wires, and hoses from damage caused by friction, sharp edges, and other abrasive elements.

Longevity and Durability: Kevlar is a highly durable material that can withstand harsh conditions and repeated use. Kevlar Braided Expandable Sleeving offers long-lasting protection, reducing the need for frequent replacements and maintenance.

Easy Installation and Maintenance: The expandable nature of the sleeving allows for easy installation and removal, simplifying the process of adding or replacing cables, wires, or hoses. It also facilitates inspections and maintenance of the protected components.

Versatility: Kevlar Braided Expandable Sleeving is suitable for a wide range of applications across various industries, including automotive, aerospace, marine, robotics, and more. Its versatility makes it a preferred choice for protecting cables, wires, and hoses in diverse settings.

These advantages make Kevlar Braided Expandable Sleeving a reliable and effective solution for protecting and enhancing the performance of cables, wires, and hoses in demanding environments.

|

| What are the advantages of using Kevlar Braided Expandable Sleeving? |

Comments

Post a Comment